Rethinking handstand blocks for traveling

Heidi is an impressive yoga and acroyoga teacher and practitioner. We met because we share a passion for highlining. Ok, let's get back on point! Heidi was planing a world tour teaching acroyoga and told me she wanted handstand blocks. I love when people approach me with an idea and we collaborate to bring it to life. The goal was to minimize space and weight usage without compromising functionality. Oh, and you can get them in the store.

A block designed for strength, weight and space

Most handstand blocks on the market are made of hardwood or stacked plywood. It is great but heavy, at roughly 500 grams a block. If you travel with 4 like Heidi does, it is an extra 2kg in your luggage! And unfortunately softwoods (which are also lighter) are too fragile.

We quickly got to the idea of building a hollow box to save on material and reduce the weight. The challenge of a hollow box is to make it sturdy enough to support some abuse; handstand blocks usually get tossed around quite a bit and after all we are putting all our body weight on them.

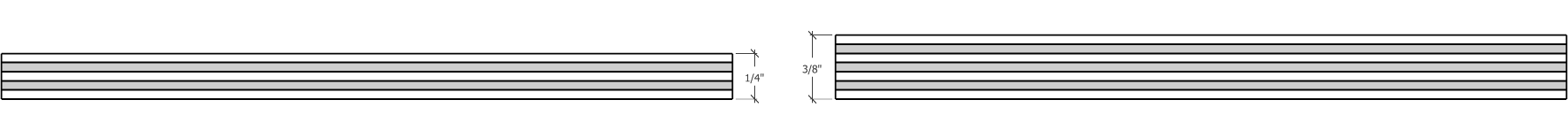

I turned to my beloved baltic birch plywood. At the same thickness, plywood delivers a much greater strength than hardwood and it is also a lot easier to work with. It comes in different thicknesses. After some tests, 3/8" plywood leads to a 290g box and the 1/4" version lead to a 180g box. 1/4" really feels on the edge of what is possible in term of thickness, I don't think we can go thinner without compromising the resistance of the box.

The box is made of 6 pieces of plywood with a rabbet of half the thickness of the material all around. All the parts come together like a puzzle. It gave me that same feeling you get when you finally put the last piece and the entire thing comes together and look complete.

Once glued, it is a really solid assembly. It didn't even blink when I jumped on it. The rabbet increases the gluing surface, strengthening the joins. And because the design is symetrical, once the edge are rounded, it looks like the box are assemble with a 45 degree angle join. When function meets beauty!

When you travel with an hollow box, it can raise questions. Border agent can x-ray the box but why not make their job easier by letting them peak inside? Why not add a hole at the bottom of the block? It also means that it takes less space since you can stuff them.

The making of

When you build objects like this, it takes time to set up all the machines properly and make sure everything fits together. But once it is done, it basically consists of a lot of repetitive cutting:

Once all the parts are cut to size, I assemble and finish it. If you navigate through the pictures below it will give you an idea of the steps involved:

The blocks are availble to buy on their page.